Proper Use of Disinfectants: Dosage, Contact Time, and Surface Compatibility

The efficacy of a disinfectant depends largely on its concentration. Many products are designed to be diluted according to the manufacturer’s specifications, while others come pre-mixed. It’s essential to follow the recommended dosage for optimal performance. Overdilution can reduce the effectiveness of the disinfectant, leaving surfaces inadequately sanitized, while using too high a concentration can lead to toxicity, surface damage, or health risks for users. At our company, we provide disinfection products with clear, easy-to-follow instructions on dilution ratios, ensuring that you always achieve the correct balance for safe and effective use.

Contact time, or dwell time, refers to the period during which the disinfectant must remain wet on a surface to effectively kill pathogens. Different disinfectants have varying required contact times, typically ranging from 1 to 10 minutes, depending on the active ingredients and the type of pathogens targeted. Failing to adhere to the specified contact time can leave harmful microorganisms alive on treated surfaces. Our disinfection products are formulated for fast action, reducing the necessary contact time without compromising effectiveness, making them ideal for both high-traffic areas and time-sensitive environments like hospitals and offices.

Not all disinfectants are suitable for every surface. Certain chemicals may damage sensitive materials like wood, fabrics, or electronics, while others may cause corrosion or discoloration over time. Understanding surface compatibility is crucial for choosing the right disinfectant for a specific application. Our products are engineered with surface compatibility in mind, providing a wide range of solutions for different surfaces, from hard, non-porous surfaces like countertops and floors, to softer materials like upholstery and medical devices. By offering versatile, safe disinfectant options, we ensure that surfaces remain intact while pathogens are effectively neutralized.

Understanding the Differences Between Cleaning, Disinfecting, and Sanitizing

Cleaning refers to the removal of dirt, debris, and impurities from surfaces. It involves the use of soap or detergents combined with water to physically eliminate visible particles. While cleaning reduces the number of germs, it does not necessarily kill them. This process is essential as a preparatory step before disinfecting or sanitizing, as it clears away substances that might impede the effectiveness of disinfectants. Our disinfection products are designed to work on pre-cleaned surfaces, ensuring maximum efficiency once dirt and debris are removed.

Disinfecting goes beyond cleaning by using chemical agents to kill germs and pathogens on surfaces. Disinfection is crucial in healthcare settings, public spaces, and homes where the risk of infection is high. It targets harmful microorganisms like bacteria and viruses, ensuring that they are neutralized. To achieve effective disinfection, products must be applied correctly, adhering to dosage, contact time, and surface compatibility guidelines. Our disinfection products are scientifically formulated to eliminate up to 99.9% of harmful pathogens, offering fast-acting, reliable solutions for high-risk areas.

Sanitizing is the process of reducing the number of germs on a surface or object to safe levels as determined by public health standards. Unlike disinfecting, which aims to kill nearly all pathogens, sanitizing is more focused on lowering the germ count to minimize the risk of infection. It’s often used in food preparation areas or places where a high level of sterility isn’t necessary but a clean environment is essential. Many of our disinfection products are versatile enough to be used for both disinfecting and sanitizing, depending on the specific needs of the area.

English

English русский

русский Español

Español

Aerosol Cosmetics

Aerosol Cosmetics

Facial Care

Facial Care

Body Care

Body Care

Antibacterial And Sterilizing Pet Shampoo

Antibacterial And Sterilizing Pet Shampoo

Daily Necessities

Daily Necessities

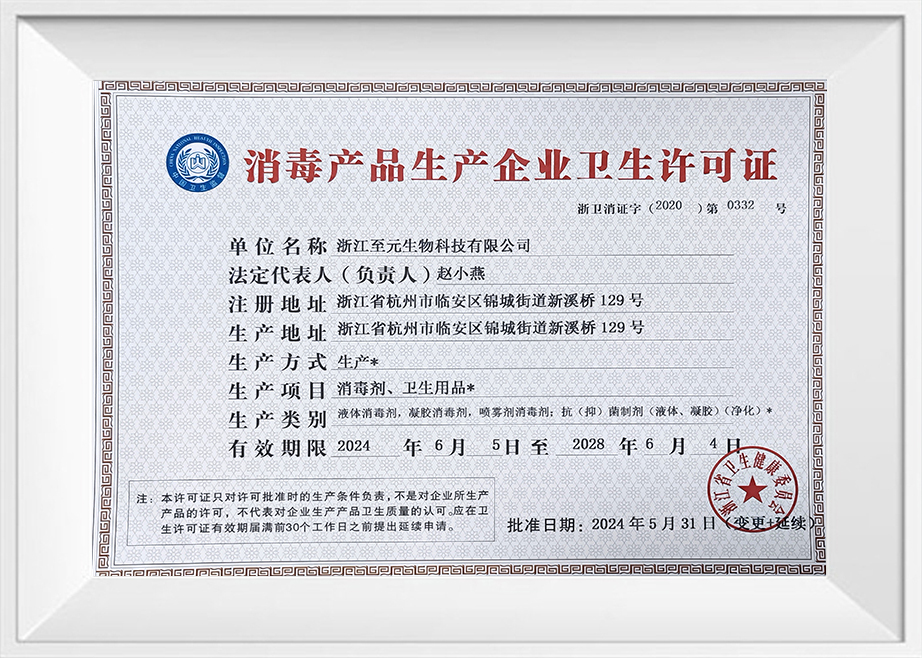

Disinfection Products

Disinfection Products